No products in the basket.

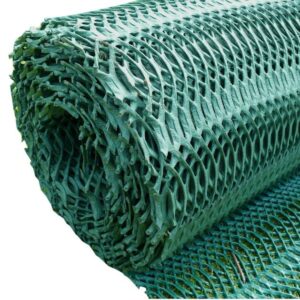

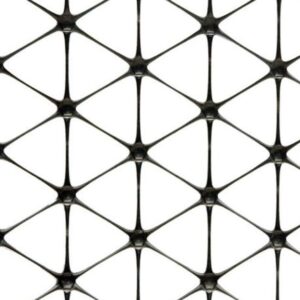

Geotextile Membranes (Woven & Non-Woven)

Stocking a range of trusted brands like Terram, our range of geotextile membranes are perfect for a wide variety of applications, from lining drains, wrapping soakaway crates to construction and engineering purposes.

The most common sellers are the white non woven geotextile membranes and black woven geotextile membranes. These fabrics function by blocking debris or separating aggregates while allowing water to pass through. They are used for a huge range of purposes but no matter what you’re using it for, our geotextile membranes are the big brand products used by top construction and civil engineering companies across the UK.

Most can be ordered in a custom size for your convenience, saving you money and waste on extra membrane you don’t really need.

Additionally, you can look forward to fast and accurate delivery on any products you order from EasyMerchant. If you aren’t sure exactly what kind of geotextile membrane is best for your purposes, you can get in touch and have a chat with one of our experts.

Sale!

Sale!

(12)

From £17.89 Excl. VAT

Sale!

(1)

From £41.59 Excl. VAT