No products in the basket.

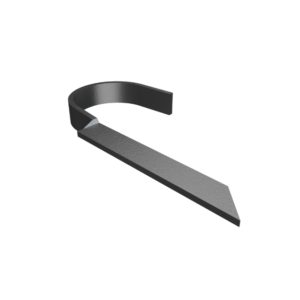

Primed Cast Iron Downpipes & Fittings

Within this category you will find all of the cast iron down pipe, fittings and accessories compatible with our cast iron guttering products.

The cast iron rainwater downpipe offers not only a strong visual appeal but also incredible reliability, performance and best of all sustainability, ideal to complete a traditional guttering system.

We can supply cast iron gutter supplies in a range of colours which are delivered within 7-10 working days. Primed / mill finished items are delivered within 4-5 working days.

- These are bespoke items made to order and are non-refundable.

- We are charged a flat rate for shipping of £54 by the manufacturer, so this range does not quality for free shipping.