No products in the basket.

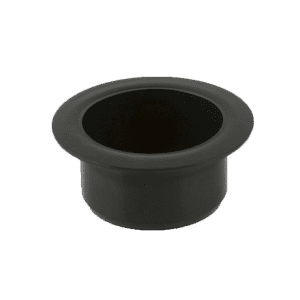

Inspection Chambers & Manhole Bases

An inspection chamber or a manhole is an access point for any pipework or underground drainage system. Contractors use it to carry out maintenance work, cleaning, or removing blockages, for example.

We keep a range of manhole bases & inspection chambers to suit all needs. All manhole bases are kitemarked and BBA approved for use within the UK. Both are compatible with our 110mm or 160mm Drainage categories.

Sale!