No products in the basket.

Blog

Soil Vent Pipe Building Regulations UK – Summarised.

In this blog post we’ll summarise some of the most relevant soil vent pipe building regulations for UK installations.

Before we get going, we should explain some of the terminology used within this blog post:

- A ‘soil stack’ is the pipework system that takes the waste water from the plumbing in the upstairs of a building and runs it down the side of a property and into an underground drainage system.

- A ‘water seal’ is a seal formed by water to prevent gas passing through.

- A ‘trap’ is a fittings that forms a water seal put between soil vent pipes and other externalities.

- A ‘branch’ is a part of the pipe system that allows one pipe run to split into two, or a means to attach another pipe run into a main pipe run.

- A ‘discharge pipe’ is a kind of pipe where unwanted fluids can be discharged.

- ‘Sanitary pipework’ is pipe work that is not underground.

- A ‘stub stack’ is a shortened version of soil vent pipe which has an air admittance valve fitted in order to suppress unwanted smells.

- A ‘condensate drain line’ is part of a heating, ventilation and air conditioning unit. There is a large area beneath the system that collects condensation and sends it towards the pipe system so that it can be disposed of.

- A ‘condensate trap’ is the area where condensation is collected before it is sent to the drain line. It is often referred to as the ‘pan’ which is also part of the condensate drain line.

- + not more than 1 WC with outlet size less than 80mm

- * No WCs

- An ‘air trap’ is a clear vertical area between the water outlet and flood level of the actual installation.

Information on soil pipes can be found in the sanitary pipework section of the government’s Drainage and waste disposal: Approved Document H.

Summary of the regulations on traps.

A trap is a fitting that creates a water seal between the soil vent pipes and other externalities. There are different types of traps for indoor and outdoor use. They are put in place to stop any unwanted odours or bacteria returning back through the waste pipe. In accordance with the UK government regulations, traps should be able to retain a minimum seal of 25mm of water. Trap sizes and seal depths vary for different uses and applications; for example a low back p trap would be used outside the house to introduce rainwater pipes to a foul drain, whereas a regular p trap would be used below a sink as part of sanitary pipework. A list of the most common sizes can be found in the government document on sanitary pipework in the traps section. These sizes are for above ground pipework (sanitary pipework) like a sink or a shower.

Examples of water traps used externally, would include:

How to connect the soil stack to the underground drainage system?

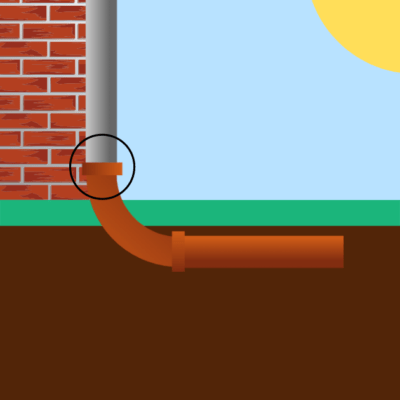

The soil stack can be connected to the underground drainage system either by simply joining onto the pipe using a bend or coupler as illustrated below:

Or, it can be fitted into a bottle gully, gully trap, or low back P Trap. As discussed above, fitting the stack into a suitable trap will stop harmful gasses and smells from entering the property.

Summary of the regulations on branch discharge pipes.

A branch pipe is essentially a length of pipe that has various inlets and outlets which accept new pipe runs into the main pipe. The rule of thumb is that the branch pipe should discharge into another branch pipe or a system that runs vertically through all of the floors in the building you are working on. This is also known as a ‘discharge/drainage stack’. The only exception is if the discharge goes straight into the gully, as the majority of the time gullies are located at the floor level of a building and may even be located in a basement or cellar. Make sure that you don’t allow for any discharge to flow straight into a hopper as this would detract from the rules around branch discharge pipes. However, if your project has branch pipes on the ground level of the property they can discharge to a: stub stack, discharge stack, straight to the drain and even directly to the gully (providing it is only rainwater). Furthermore if you are in a position to have a branch pipe discharge directly to a gully it should stop between the sealing plate and the top part of the water seal.

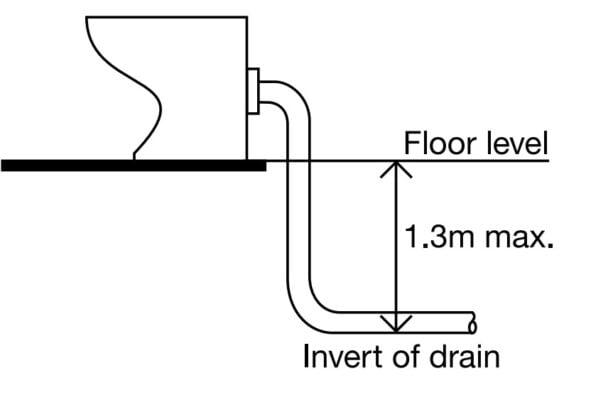

In some situations pipe from your ground floor closet can directly get rid of water when the depth from the floor to the drain has an invert of 1.3 meters. This is the maximum invert allowed without breaking the rules and regulation put in place by the government. The diagram shows this in further detail.

When you are fitting various branch pipes as part of a stack system, the angles of each branch can on occasion cause a crossflow of water from one branch to another. This will lead to internal problems within the system and breach the guidelines so you must take this into consideration when installing the pipework. Another important point to remember with a stack system is that its not allowed to have a discharge pipe connected to it unless it is a minimum of 450mm above the upper part of the bend, at the very bottom of the stack. Just for reference this principle applies to buildings no larger than three stories – however, if your job suits this method, you may send the discharge pipe to a cut off version of soil vent pipe also known as a ‘stub stack’. This is shortened pipe with an air admittance valve connected to the end.

Quick tip! It is important to make sure that any bends used have as large a radius as possible to maximise the flow capacity.

When dealing with junctions on branch vent pipes with identical diameters, they should have a sweep (radius) of 45 degree. This is because having ‘sweep’ will allow for the flow resistance to be reduced when the direction of flow is changed. When connecting branches with 75mm diameter to a stack with the same diameter, they should also be made with a 45 degree sweep. More on joining and connecting branches can be found in detail in the government documentation. It is also worth noting that there is no need for separate air ventilation with branch pipes, which is handy on a big installation.

The term sanitary pipework is thrown around regularly, so just to clarify, it is any kind of pipework that is used to transport waste water (grey water) from toilets, sinks, baths, washing machines, dishwashers etc into the underground drainage system. A condensate drain line from a boiler is also classed as sanitary pipework. A condensate drain line sends the collected water from the condensation towards the pipe system so that it can be disposed of. Upon making this type of connection make sure to use pipework that has a diameter of 22mm, as a minimum, that goes through a 75mm condensate trap. A condensate trap is there to ensure that the condensation released by your boiler is safely collected so that it doesn’t affect anything in a negative way. In the case that there is an extra condensate trap provided to the boiler, an air gap should be implemented in between the boiler and the free space. An air gap is a clear vertical area between the water outlet and flood level of the actual installation.

Summary of the regulations on discharge stack pipe

Understanding the basic regulations surrounding soil stack venting systems is a must as an installer. In the simplest terms possible, each system should discharge to a drain and the diameter of stack should always be as large as possible. The building regs also make it clear that the radius should be at the very least 200mm at the centre line.

When installing a discharge stack, then offset bends in the “wet” section of the stack should be avoided, however under certain circumstances you might have no other option apart from to use them, if this situation occurs in a building with three floors or below, make sure that there is 750mm between each branch and offset. If you are working on a big commercial job and the building has over three floors, it is more than likely a ventilation stack will be needed which will use connection both below and above the offset. The discharge stacks should be inside of the building as well.

There are certain diameters that stacks must follow so that there are no restrictions on the direction of flow, the exact measurements are as followed:

50*mm stack size for a max capacity of 1.2 litres per second

65*mm stack size for a max capacity of 2.1 litres per second

75+mm stack size for a max capacity of 3.4 litres per second

90mm stack size for a max capacity of 5.3 litres per second

100mm stack size for a max capacity of 7.2 litres per second

Stacks for urinals should be 50mm (2 inches) or more, for closets with outlets less than 80mm (3.14961 inches) they should be 75mm (2.95276 inches) and for closets with outlets more than 80mm (3.14961 inches) then they should be 110mm (4 inches) at a minimum. Make sure that the inside diameter of the stack is at least the same diameter as the biggest trap or branch discharge pipe, this will ensure that the system’s ability to flow is not stopped or hindered in any way.

An important thing to bear in mind with discharge stacks is that it’s a necessity to have them ventilated. The key reason for this is so that water seals are not lost due to pressure build up in the discharge system. Often a stack can be connected to a drain prone to expanding in size due to external factors or can even be in the same area as an intercepting trap. When this happens it is important that a ventilation pipe of at least 50mm is connected to the lower part of the stack but must remain above the likely flood level. For some projects a stub stack will need to be used which is a shortened version of a soil vent pipe that connects to an air admittance valve. For this set up, firstly be certain that it is not connected to a water closet with a base level of more than 1.3m. From here, connection to a ventilated discharge stack or a ventilated drain is crucial. If it is a two story or less sized house you are working on then pipes of a minimum 75mm may be used. Be aware and make sure that the stack or drain will not change in size over time.

Air admittance valves, rodding eyes and pressure testing.

Ventilated soil stack vent pipes can be installed inside a building if you choose to fit them with air admittance valves. The role of an air admittance valve is to allow air into the system and control the pressure inside of the pipes. The way this works is the valve inside of the pipe opens to let air in and balance the pressure levels out if they start to fall negative. This somewhat maintains an integral part of the system. The valves need to be fitted in a place with sufficient ventilation while also being accessible for maintenance and along with being removable. Remember to keep air admittance valves inside of buildings and out of the way of areas where heavy dust is an issue. You can read more about air admittance valves here

Rodding points are used as a point of access to important pipework and when fitted in stacks should be above the spill over level of any instruments used in the system. They give access to parts of the system which may not be available from anywhere else, allowing them to be maintained and cleaned easily. They should always be situated upright so that if there are blockages they will flow away downstream.

By legislation, ventilation pipes must be able to handle an air test of 38mm of pressure on a water gauge for three minutes. A 25mm water seal should be maintained. It is important to always test pipes after an installation because if there is not the right balance in pressure, it could even lead to burst pipes. Along with this, in the winter months an inconsistency in pressure may lead to things such as dried up taps as well as various other problems. So to ensure your whole system runs as it should make sure to correctly carry out the drain testing procedure. For more information on testing pipework properly you can see our ‘All about drain testing’.

As with any job being undertaken, good workmanship is a necessity. Ensuring that your work is to a high standard enhances the overall reliability and performance of the system that is being fitted. This can help save money down the line and extra work! It is also crucial that the work taken place falls in line with the government rules, to ensure that your soil pipe drainage system is running as it should be. If you are unsure on matters spoken about in this blog post, you can make reference to the government regulation via the link at the top of this page.

Shop Soil Pipe:

Sale!

Sale!

can you use a Flexi pipe on internal stench pipe as can’t get solid pipe between timbers in loft

Hi John,

Flexible soil pipe does exist, although we do not stock it, and this can be used as part of the soil stack for tight spaces.

You will need refer to Document H, which specifies the materials that can be used within the stack, to ensure that this meets regulations.

I hope this helps!

Kind Regards

Lainey

Can you use metal pipe or do they need to be plastic now

Does the air admittance valve have to be 110mm on a new build and terminate in the loft space the site is really tight for space and possible remedy would be to use a 50mm (2”) air admittance valve ?

Hi Chris. I’ve just found this on em website and have the same issue. Did you ever get a response? I’m also short of space and want to go for 2″ rather than 4. Presumably you’ve installed the pipework now so I guess it either worked or didn’t!? Cheers

Mike

Hi Chris,

I believe the answer to this is no, soil pipes need to be 110mm at least to help prevent blockages. Also I think a 50mm air admittance valve will struggle to pull enough volume of air in for a 110mm soil stack.

I hope this helps.

Hi, my builder connected a SVP into a Rain water outlet that discharges on to the road. What can I do if they haven’t worked to Building Regulations?

Hello – can the SVP run horizontally beneath roof before going downward into manhole?

How many floors and bathrooms can a 110 dia upvc pipe can serv

Hi Chris. I’ve just found this on em website and have the same issue. Did you ever get a response? I’m also short of space and want to go for 2″ rather than 4. Presumably you’ve installed the pipework now so I guess it either worked or didn’t!? Cheers

Mike

does the svp have to go past the gutter height or can i run it up the wall and put a mushroom on it.

yes is the short answer however, you must fit an air admittance valve

Hi

My neighbour next door ventilated soil pipe which come from underground is fitted under my window which supposed to be fitted 900mm above any window.

He is refusing to accept this is against role and regulations. Do I have right to complain? If yes where do I have write to please?

Thank you

Contact your council/local authority who will come round to inspect it.

Rats are accessing my loft through the space around a boxed in soil pipe. Can I safely cut through the boxing?

Hi there, i moved into a new build home in early 2021, I noticed moisture in my bathroom ceiling and thought nothing of it. Fast forward 2 years later and soaking / deformed cieling was cause for concern.

I checked in my loft to find I have an SVP with a section of pipe incorrectly pointing downwards creating a concentrate trap in the pipe, before it then goes back up and exhausts through a roof vent tile. The pipe is fitted together with electrical tape and not at the correct angle. NHBC dont cover it and the builder refuse to acknowledge anything is wrong after 2 years… can I ask for any advice please on where it states there needs to be an incline on vent pipes to avoid this?

Any feedback most welcome!

Hi, I’ve been told that my soul & vent pipe need to be raised my question is why & how much will it cost for a Plummer to do this